The Excalibur GDi Master is a plug-and-play test bench capable of powerful flow and high frequency injection rates that allow it to test coil and piezo injectors of both GDi and PFI technology types in as little as five minutes.

The growing GDi injector market introduces new and fast-changing technologies for which Hartridge and Delphi Technologies can provide cutting-edge test solutions to the workshop. GDi testing in as little as five minutes with Hartridge “Building on our pioneering OE expertise, our GDi solution provides technicians with everything they need to perform premium end-to-end service with access to leading all-makes diagnostics and test solutions that can increase vehicle uptime and garage profitability over 30%.” “The GDi equipped new vehicle market is expected to grow by more than 10 percent annually through 2026, which presents an exciting opportunity for the aftermarket,” said James Tibbert, EMEA marketing director, Delphi Technologies Aftermarket. By expanding its product offering to more than 3 million Hyundai and Kia models, the company increases its total number of premium end-to-end service opportunities by more than 75 percent for its aftermarket customers.

Along with its pioneering GDi product portfolio, the aftermarket solution features comprehensive training, advanced diagnostics, testing and cleaning equipment, technical service, cataloging and market data. Its comprehensive GDi solution already consists of pumps, injectors and service kits fitted as OE to more than 3.9 million popular PSA vehicles. The second pattern is powering up the fuel injector and contains a small voltage spike at the same time as the amperage goes up.Profitable end-to-end service opportunities for a growing marketĪs a leading manufacturer of OE GDi technology with 30 percent market share worldwide, Delphi Technologies extends its pioneering OE expertise to the aftermarket. If you go into your lab scope you can see two different patterns displayed, one after the other. That’s where the connection is made for this example. The tool tells you that the best place to test on these vehicles is either at the injector itself, which can be hard to reach, or a 16-pin connector on the left rear side of the engine, above the engine oil filter housing.

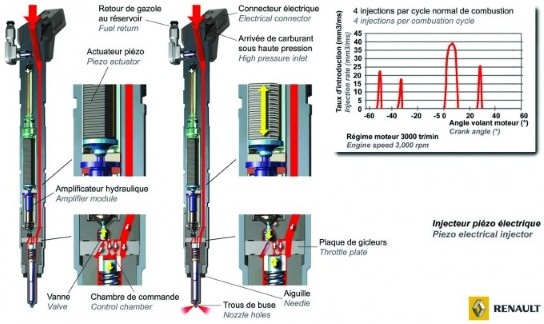

#PIEZO INJECTOR TESTING BORDERS DRIVER#

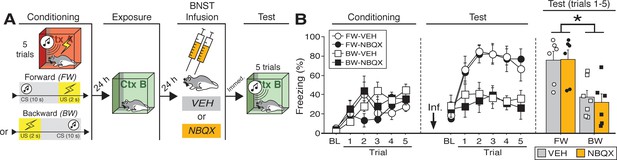

The PCM contains a smart driver that actually monitors each side to see whether there's a problem and it will display a code for whatever the problem happens to be If boost voltage is unavailable, the correct injector opening current might not be generated in the time required The injector driver controls three transistors switches that apply the boost voltage to open the injector and then modulates the current to hold the injector open The gasoline direct fuel injector delivers fuel directly into the cylinder under high pressure.Įach injector is controlled by two circuits from the PCMĪ boosted voltage supply up to 65 volts is generated in the PCM and used to initially open the injector Now the tool going to give us some information so we'll go into Component Information and it tells you how the system operates: With the vehicle identified, go into the Fuel Injection System menu and then into Fuel System, followed finally by Fuel Injector. Inside all of the Snap-on scope tools is the Guided Component Tests section, which gives us a lot of information on how things work and where to connect the tool to the vehicle – let’s use a 2016 Ford Escape with an EcoBoost ® motor for this example. With a Snap-on scan tool hooked up to the vehicle, we can see how the data looks on a lab scope and how the pattern is actually different than a standard fuel injector. Manufacturers had been using this system on diesel vehicles for quite some time so if you've never worked on a diesel you might not know it's a little bit different. It's a far more efficient way of injecting fuel into the engine. Did you know that fuel injectors on Direct Injection vehicles work differently than a standard fuel injector?Ī lot of newer cars use petrol direct injection.

0 kommentar(er)

0 kommentar(er)